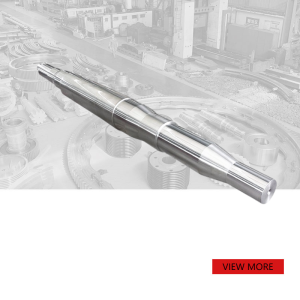

Large Gearbox Custom Forged Spiral Bevel Gear Shaft

PRODUCT PARAMETERS

Description

1. Bevel Gear Overview

Bevel gears are also called bevel gears, bevel gears. They are used for transmission between intersecting shafts. Compared with cylindrical gears,

they can change the transmission direction. The single-stage transmission ratio can reach 6, and the maximum is 8.

Bevel gears are divided into straight bevel gears, and spiral bevel gears, etc.

2. Product Description

We can produce large forged, cast and welded gears according to customer drawings. According to working conditions and customer requirements, we can also perform gear grinding, surface hardening, surface quenching, nitriding quenching, etc.

3. Features

-The tooth shape of the spiral bevel gear is an arc shape, and it is generally conical, like an umbrella, hence the name spiral bevel gear.

-Spiral bevel gears have high transmission efficiency, stable transmission ratio, large arc overlap coefficient, high load capacity, smooth transmission, reliable operation, compact structure, energy saving and material saving, space saving, wear resistance, long life and low noise.

Parameter table

- Application

Our large spiral bevel gears are mainly used for large equipment. Such as rotary kilns, ball mills, dryers, and dragline excavators.

The role of gears is mainly to transmit power. It can transmit the rotation of one shaft to another shaft. Different gear combinations can play different roles, which can realize mechanical deceleration, acceleration, change of direction and reversing. Basically, mechanical devices cannot do without gears.

5. Production process

– Forging blank

– UT test

– Heat treatment

The heat treatment of the cast gear ring includes normalizing, quenching and tempering to improve hardness and toughness. The gear ring is heated to a specific temperature in a high temperature furnace, then cooled rapidly, and finally tempered to stabilize the organization, ensuring mechanical properties and dimensional accuracy.

– Finishing

– Packaging

6.Our advantages

– Professional, specific furnace, single-minded

– Vertical pit furnace, keep temperature uniform when heating, +/-1 ℃

– Small deformation, less oxide layer, reduce material cost

– Different materials can be cooled at the best speed

– Large capacity, complete various quenching media: oil, water, brine, water-based mixture.

REQUEST A QUOTE

RELATED PRODUCTS

Spur gear shaft forging high quality large diameter Ball Mill

Mining high quality forging Helical gear shaft

Custom Mining Crusher large heavy main cone shaft

34CrNiMo6 Alloy steel Helical gear shaft rotary kiln

Spur gear shaft forging high quality large diameter for Ball Mill