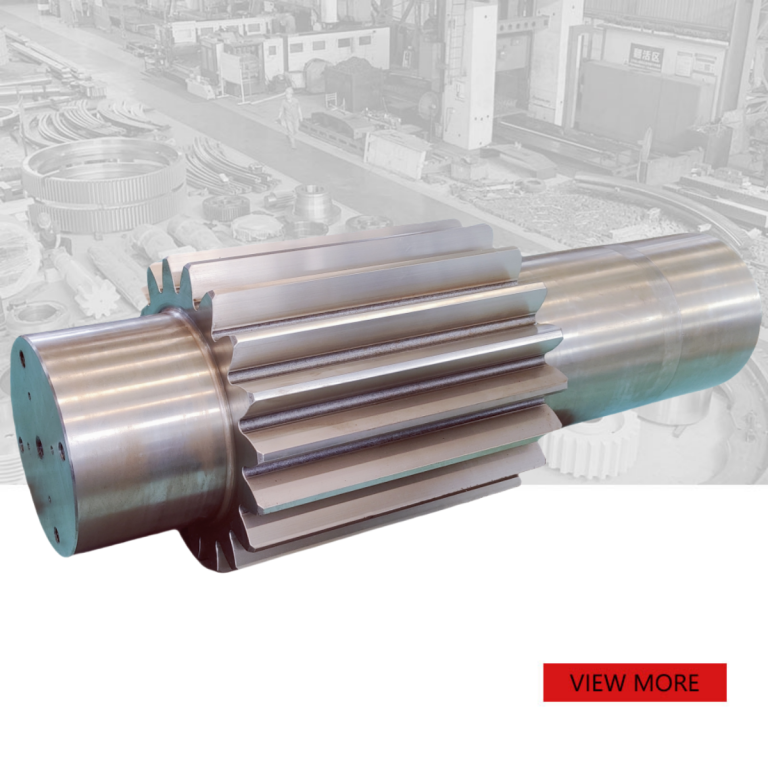

Mining high quality forging Helical gear shaft

PRODUCT PARAMETERS

Description

Overview of Helical Gear Shaft

A Helical Gear Shaft is a key component in a mechanical transmission system that transmits motion and torque by one or more pairs of helical teeth meshing with each other. Compared with spur gears, helical gears have smoother running characteristics and higher load carrying capacity.

Production process of Helical Gear

Compared with the helical gear production process, the helical gear shaft needs to pay more attention to the following two points:

Material selection of Helical Gear Shaft:

Choose the right material according to the application needs, usually alloy steel (such as 40Cr, 42CrMo, etc.), these materials can obtain good mechanical properties after heat treatment.

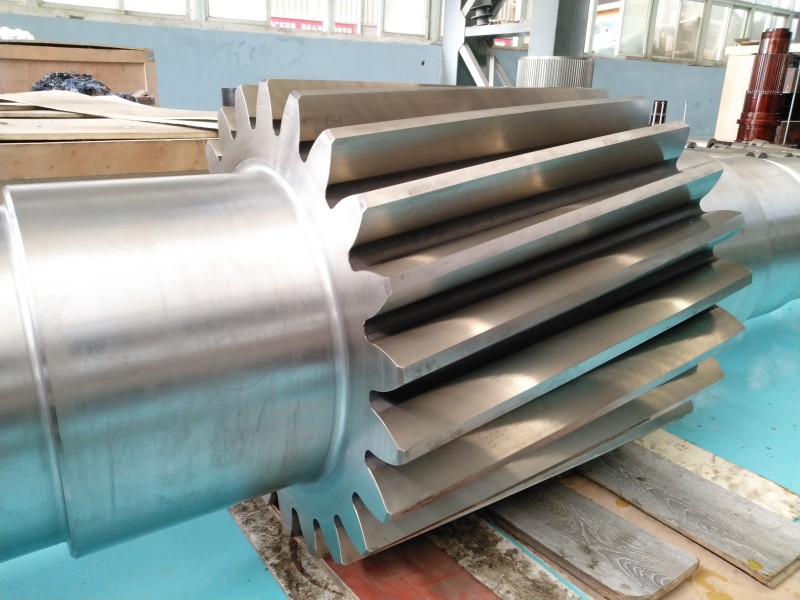

Precision machining of Helical Gear Shaft:

In order to ensure accurate meshing accuracy and good surface finish, spiral gear shafts often need to undergo strict heat treatment, grinding and other finishing processes.

Application of helical gear shaft in mining machinery

1.Mine excavator

-Slewing support: The slewing support between the excavator chassis and the superstructure is also often a helical gear shaft, allowing the machine to rotate 360 degrees in all directions, improving the flexibility of operation.

- Crusher drive: The main shaft and eccentric shaft inside the jaw crusher, cone crusher and other equipment are usually driven by helical gear shafts, which are responsible for converting the power of the motor into the reciprocating or rotating motion required for crushing parts.

Parameter Table of Helical Gear Shaft

| Material | Carbon Steel , Alloy Steel |

| Diameter | 1000-8000mm |

| Width | 200-1500mm |

| Module | 8-100 |

| Gear Grinding | MAX Module 25 |

| Heat Treatment | Q&T |

Package of Helical Gear Shaft

The internal liner or bracket is customized according to the specific size of the helical gear shaft to ensure that the gear shaft will not move in the case and reduce the damage caused by vibration. It is then placed in a custom fumigation-free plywood box.

FAQs of Helical Gear Shaft

-What parameters should I consider when choosing a helical gear shaft?

-The following parameters are mainly considered: modulus, number of teeth, spiral Angle, pressure Angle, outside diameter, inside diameter, width, center distance, transmission ratio, maximum torque, allowable speed, bearing capacity, material hardness, surface treatment, etc. Make sure these parameters meet your specific needs and specifications.

-How do I find the right helical gear shaft for my application?

-It is best to consult a professional supplier or manufacturer to provide detailed application information (such as working conditions, required power, speed range, etc.), and they can recommend the most suitable product according to your needs. In addition, looking at product catalogs and technical manuals are also good sources of reference.

-What are the price factors of helical gear shaft?

-The price is affected by a number of factors, including material type, manufacturing process, size, accuracy level, special coating or treatment. In general, high-quality, high-performance helical gear shafts are relatively expensive, but can reduce maintenance costs and extend service life in the long run.